Flexible solutions that grow with your needs

Turn information into action today.

We’ll help you to choose the best plan for you.

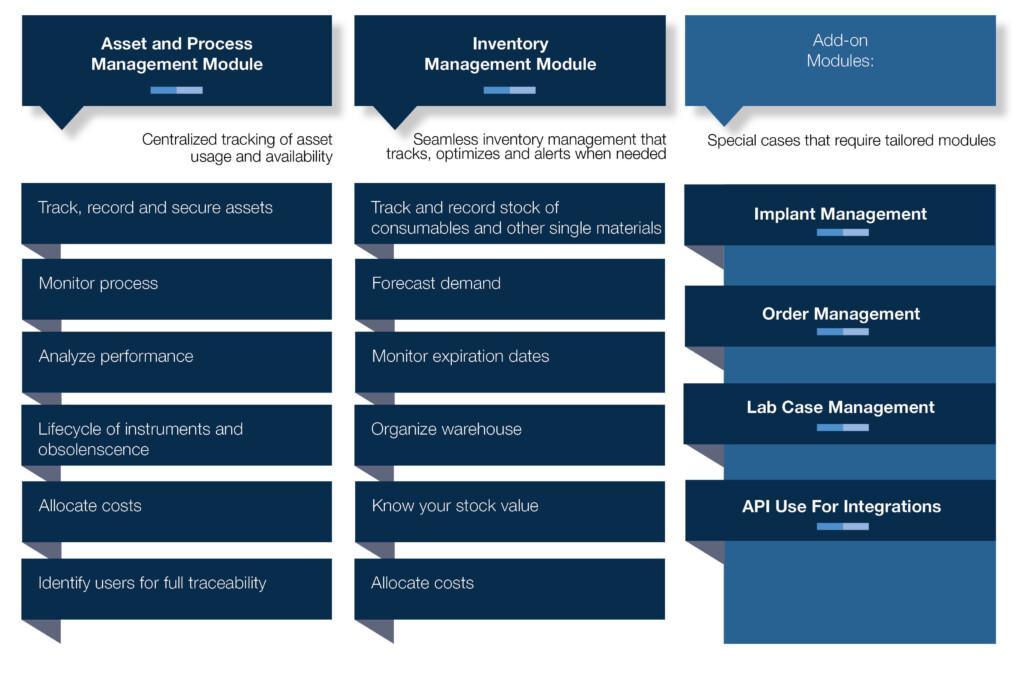

Product Modules

Asset and Process Management Module

Centralized tracking of asset usage and availability

The LM Dental Tracking System™ Asset and Process Management Module simplifies dental asset handling and traceability. It manages clinic processes, instrument reuse, and the dispensing and storage of dental instruments.

This system automates tracking, reduces manual checks, enhancing efficiency and saving time. It ensures adherence to processes, and alerts users to deviations, supporting patient safety.

Scalable and adaptable, the LM DTS™ module is an invaluable tool for dental practices, offering complete control over assets and efficient process management.

Inventory Management Module

Seamless inventory management that tracks, optimizes and alerts when needed

The Inventory Management Module offers seamless inventory management by tracking, optimizing, and alerting when needed. It maintains control over consumables and dental materials by tracking their location, usage, and process stage.

The module forecasts future demand using historical data, monitors expiration dates to ensure patient safety, and organizes warehouse storage for easy access. It also helps manage costs and budget by providing a clear overview of inventory value and details.

The determination of the customer-specific solution starts with core need identification

To begin the solution planning process, it is essential to first understand the current situation at the clinic, including identifying any existing problems and setting clear targets. This core need identification will guide the subsequent steps, which include analyzing the flow of assets within the clinic, identifying the critical steps in this flow, and determining what needs to be tracked and how to track it. Our system is fully configurable to meet any local regulatory or quality requirements, as well as your unique needs.

DO YOU NEED HELP IN IDENTIFYING THE BEST OPTION FOR YOU? SIGN UP FOR A FREE EVALUATION

We help you identify your need and choose the best solution.

LM Dental Tracking System™ use cases

Efficient implant management at Virginia Commonwealth University

Virginia Commonwealth University (VCU) School of Dentistry encountered significant challenges in implant management due to the absence of a dedicated tracking system. Consequently, manual management processes resulted in various issues, including financial losses from the ineffective use of expired implants. Discover how successful implementation of an implant management system led to remarkable improvements.

Asset circulation management at Dental Universities

Managing borrowed instruments and assets in universities poses challenges. Manual methods lead to laborious work, missing items, and human errors. The solution? LM DTS™, a simple system for efficient lending and better accountability.

Centralized reprocessing solution for a wellbeing service county

A wellbeing services county including 20 separate clinic agreed to combine their reprocessing services into three centralized reprocessing service providers with the aim to make the process more efficient and cost effective and to crate a standardized reprocessing process for all the clinics in the county. Discover how implementation of LM DTS™ provided the clinics with a simple yet comprehensive solution for efficient maintenance operation management and monitoring of instruments.

From chaos to control: How Elegant dental clinic overcame inventory challenges

Elegant, a private dental clinic, struggled with inventory management, causing material shortages, delays, and reduced patient satisfaction. After implementing the LM DTS™ system, the clinic achieved efficient real-time inventory tracking, faster treatments, and improved patient care, leading to cost savings and better overall performance.